- Enclosure and Distribution Box should be designed as per the required specifications (Sample / Drawing in 3D or PDF Format).

- Enclosure and Distribution Box should be produced with the help of Automatic CNC Punching, Automatic CNC Bending machines for excellent quality.

- Enclosure and Distribution Box should be chosen as per the load requirements.

- Enclosure and Distribution Box should be assembled with genuine 99.99% ETP Grade Copper Basbar, MCB and other genuine components.

Welcome to

Ganga Metco

Electrical Panel Manufacturers, Distribution Boxes

Are you looking for Electrical Panels and Distribution Boxes for your Industry and Wholesale?

GANGA METCO IS HERE TO SERVE YOU

Sheet metal enclosure boxes are types of cabinet boxes which are designed to protect any electrical equipment from shock. Every box is built keeping in mind environmental protection and safety. Electrical panels are considered to be one of the safest methods of keeping electrical components protected in extreme marine conditions. Enclosures provide protection against dust, wind, water, chemicals, etc. Moreover, these are designed in waterproof material and have gaskets made from polyurethane foam. This foam provides optimum integrity and provides overall safety of the equipment.

Safety Features of Electrical Panels Manufacturers

Electrical panels manufacturers ensure the safety against any environmental damage. It helps in preventing the spread of fire in case it starts inside the box. Since it reduces the risk of fire spreading to the area, these serve as a function to save lives and more damage. These are durable and high-quality enclosure boxes which can work effectively and handle an extreme environment condition.

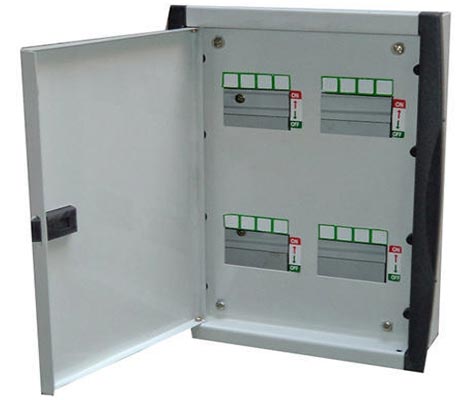

Distribution Box

Distribution boxes serve the purpose of a distributor of electrical power or load centre. It ensures electrical supply in buildings and can be commonly known by different names such as distribution panel, distribution board, electric panel, etc. Electrical distribution boxes are the main server of the central electrical supply system to any building as it divides electrical power into different subsidiary circuits and offers a protective fuse.

Power Distribution Panels

While talking about distribution boxes, power distribution panels offer great safety as it helps in distributing electricity from power source to other devices. There is one input and multiple outputs to it. As many devices are connected to power distribution boxes, they are more convenient and efficient to use. Additionally, the main benefit it offers is the ability to lower the risk of fuse or dangerous short-circuit. It comes in different sizes, shapes and construction design as these are generally customized according to the needs.

Composition of Electrical Control Panels And Distribution Boxes

Electrical Control Panels and Distribution boxes made using powder coating process alongside 11 tanks branded chemical treatment process ensure the safety, durability & longevity of the boxes. At Ganga Metco, the powder coating testing for sheet metal enclosures is done by using robust instruments such as bend and hatch test, salt spray chamber and impact tester. These enhance the quality test, which assures customers of the rigid structure of the distribution panel board. Being the best distribution box manufacturer, we curate excellent quality boxes by using material which is anti-rusting and anti-corrosion. It helps in preventing damage to the box as we use 99.99% ETP grade copper Basbar, MCB and other components. Additionally, these boxes are designed to suit particular needs of the industries, and they cater to different industrial needs. For efficient and effective boxes, we use automatic CNC bending and automatic CNC punching machines to give a more viable finishing to distribution boxes.

Ganga Metco Electrical Enclosures and

Distribution Boxes

Reliable | Sturdy | Profitable

For your Sheet Metal Enclosure and Distribution Box

requirements, please fill in the form below and submit. One of our expert will get in touch with you soon.

And/OR Call us on +91 6399394444 for instant responses.

8 Secrets tips for Good Enclosure Panels and Distribution

Box which every Industrialist must know

- Enclosure and Distribution Box should be made using Powder Coating Process with the help of 11 Tanks Branded Chemical Treatment Process.

- Powder coating testing should be done perfectly using instruments like impact tester, salt spray chamber, bend and hatch test.

- Enclosure and Distribution Box’s quality test by Third Party (Quality Checking Companies) should be done for at least 250 hours for Salt Spray Test.

- Enclosure and Distribution Box should be made with excellent quality for Anti Corrosion and Anti Rusting.

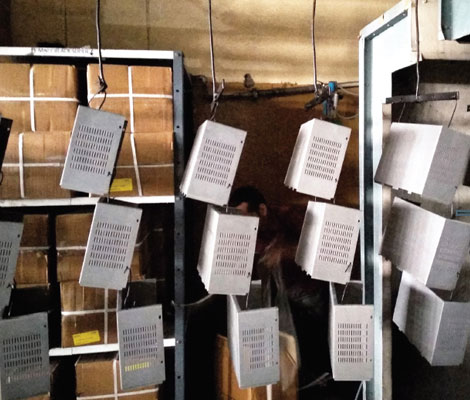

Prima Power, Automatic CNC Punching Machine working at Ganga Metco, Haridwar

We manufacture a wide range of Sheet Metal Products alongwith Sheet Metal Fabrication works

Our Products

- Electrical Box Enclosure

- Metal Enclosure Box

- Enclosure Box

- MCB Distribution Box Cover

- Sheet Metal Enclosures

- Steel Junction Box

- Small Metal Enclosure

- Metal Enclosure For Electronic

- Electrical Panel Board

- Lighting Distribution Board

- Meatel Telecom Cabinet

- Single Phase Panel Board

- Motor Panel Board

- Main Distribution Board

- MCB Distribution box

- Panel Enclosure

- Electric Control Panel Box

- Control Panel Boxes

- Telephone Distribution Board

- Outdoor Communications Cabinet

- Power Distribution Box

- Submersible Panel Enclosure

- ABS Junction Box

- IP65 Enclosure Box

- Pull box electrical

- Inverter Enclosure

- Electrical Junction Box

- Telephone Distribution Box

- Electrical Extension Box

- Modular Box

ABS Junction Box

Electrical Box Enclosure

Electrical Panel Board

IP65 Enclosure Box

Lighting Distribution Board

Main Distribution Board

MCB Distribution Box Cover

Meatel Telecom Cabinet

Metal Enclosure Box

Metal Enclosure For Electronic

Motor Panel Board

Outdoor Communications Cabinet

Power Distribution Box

Pull box electrical

Sheet Metal Enclosures

Single Phase Panel Board

Small Metal Enclosure

Steel Junction Box

Submersible Panel Enclosure

Telephone Distribution Board

For your Sheet Metal Enclosure and Distribution Box requirements, please fill in the form below and submit. One of our expert will get in touch with you soon. And/OR Call us on +91 6399394444 for instant responses.

Problems that most Industrialist and Owners around the country are facing with their Enclosures / Distribution and Boxes

- Facing 17% Rusting and Corrosion Problems with Enclosure and Distribution Box and due to this the product’s like-span gets decreased by 30%.

- 7% Dimension issues have been found during installation of Enclosure and Distribution Box.

- In different atmospheric situations, 23% paint stripping problem are found with Enclosure and Distribution Box.

- 67% Vendors do not provide suggestion and information to the customer which can reduce the cost of the product as will as can increase the quality of the product.

- 27.5% customers are not getting the right value of money for Enclosure and Distribution Box.

- Post production 3% products are found where a requirement of rework is mandatory.

- Due to increase in rejection, it affects the productivity at customer end.

- Vendors do not respond on time and do not cooperate properly after product deliveries.

- 13% products are found of poor quality because required specifications are not being followed exactly by the vendor.

- 17% product deliveries are not on time by vendor.

- 23% times the product sample is not delivered to the customer on time due to mismanagement at vendor side.

- 11 tank process for powder coating is mandatory and more reliable instead of just following the 3 tank chemical process.

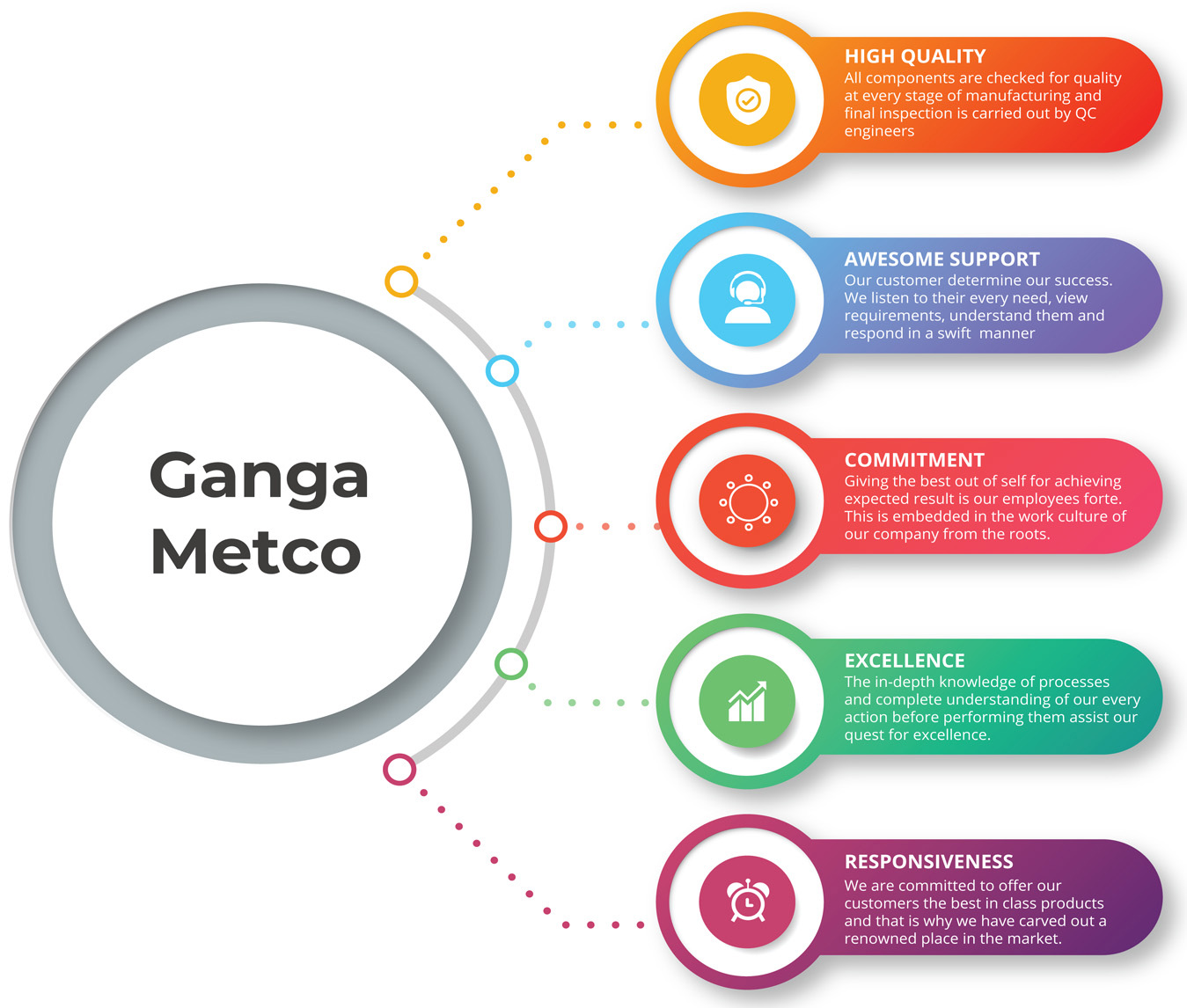

Why to choose Ganga Metco for your Enclosure and Distribution Box Requirement?

99%

Less chance of Rusty/Corrosion

97%

Higher durability Product

21+

Cities Supplying to Across India

96.5%

Rework is not required

19+

years of experience in this Industry

98%

Deliveries on Time

- We have a production facility with latest technology machines (3 Automatic CNC Punching Machines, 4 Automatic CNC Bending Machines, 40 Power Press Machines) as well as complete setup for fabrication.

- We follow the defined scientific process to maintain the highest quality with products to eliminate rusty and corrosion problems.

- Powder coating is completed with 11 tanks branded chemical treatment process and it is fully capable for a genuine and quality paint results.

- Zero rework is required with our finished products.

- We believe in delivering the best value of money and always to the customer.

- 98% product deliveries are on time.

- We provide customers the product samples as per the specifications before we start production for a bulk order (A Drawing 3D or PDF format is required).

- We have a production capacity of 190.5 tons Metal Sheet Per Month with the help of Automatic CNC Punching, CNC Bending and Power Press machines.

Our Pretigious clients

If you have questions, please feel free to

connect with us.

GANGA METCO

Plot No - 19A, IP-2, Arrow Industrial Area, Salempur Mehdood, Haridwar Uttarakhand (INDIA), Phone: +91 6399394444